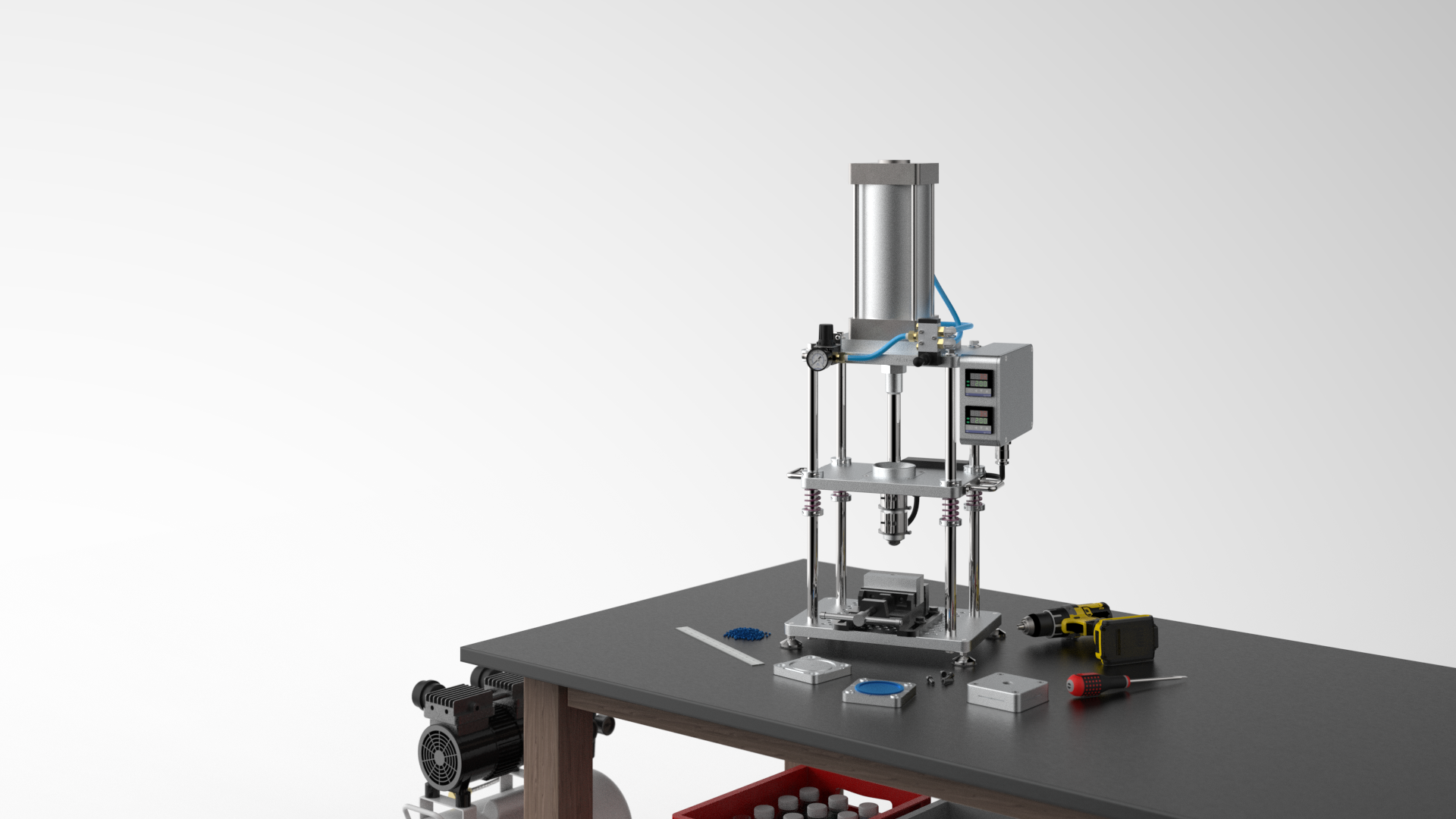

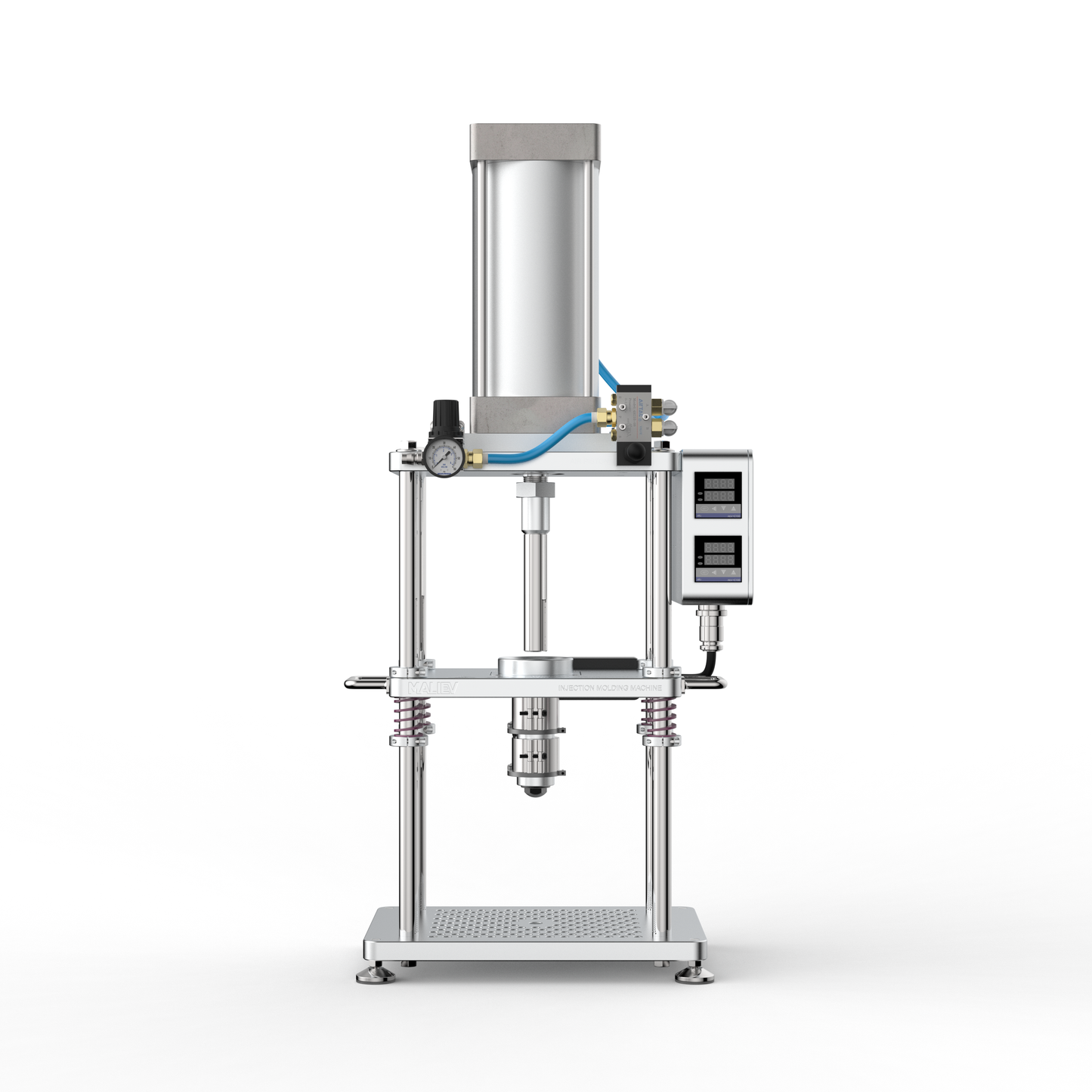

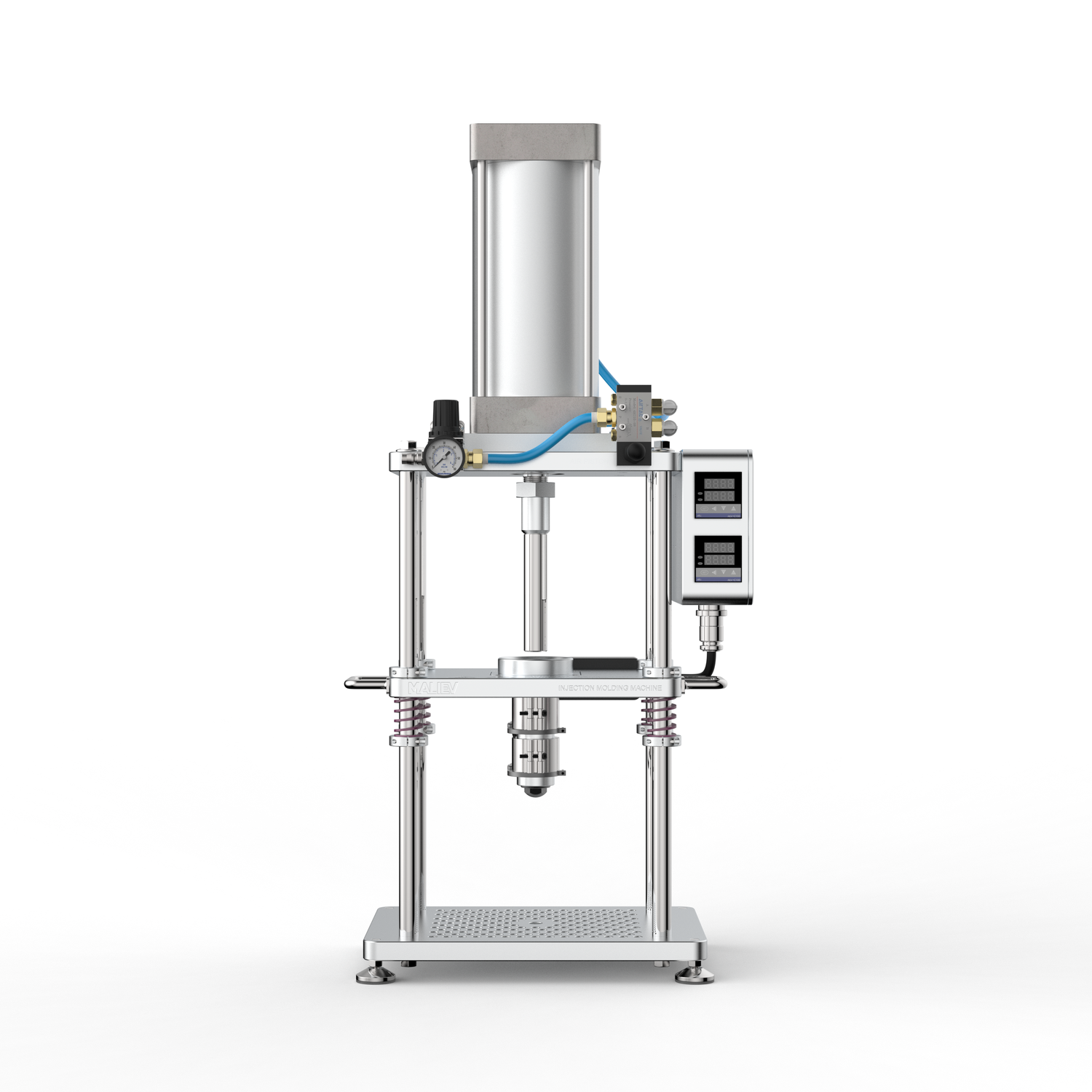

Compact and Ergonomic

Compact Design for Any Workspace

The machine fits seamlessly into any workshop or manufacturing floor. Its small footprint and ergonomic design make it an ideal choice for tight spaces while maintaining full functionality.

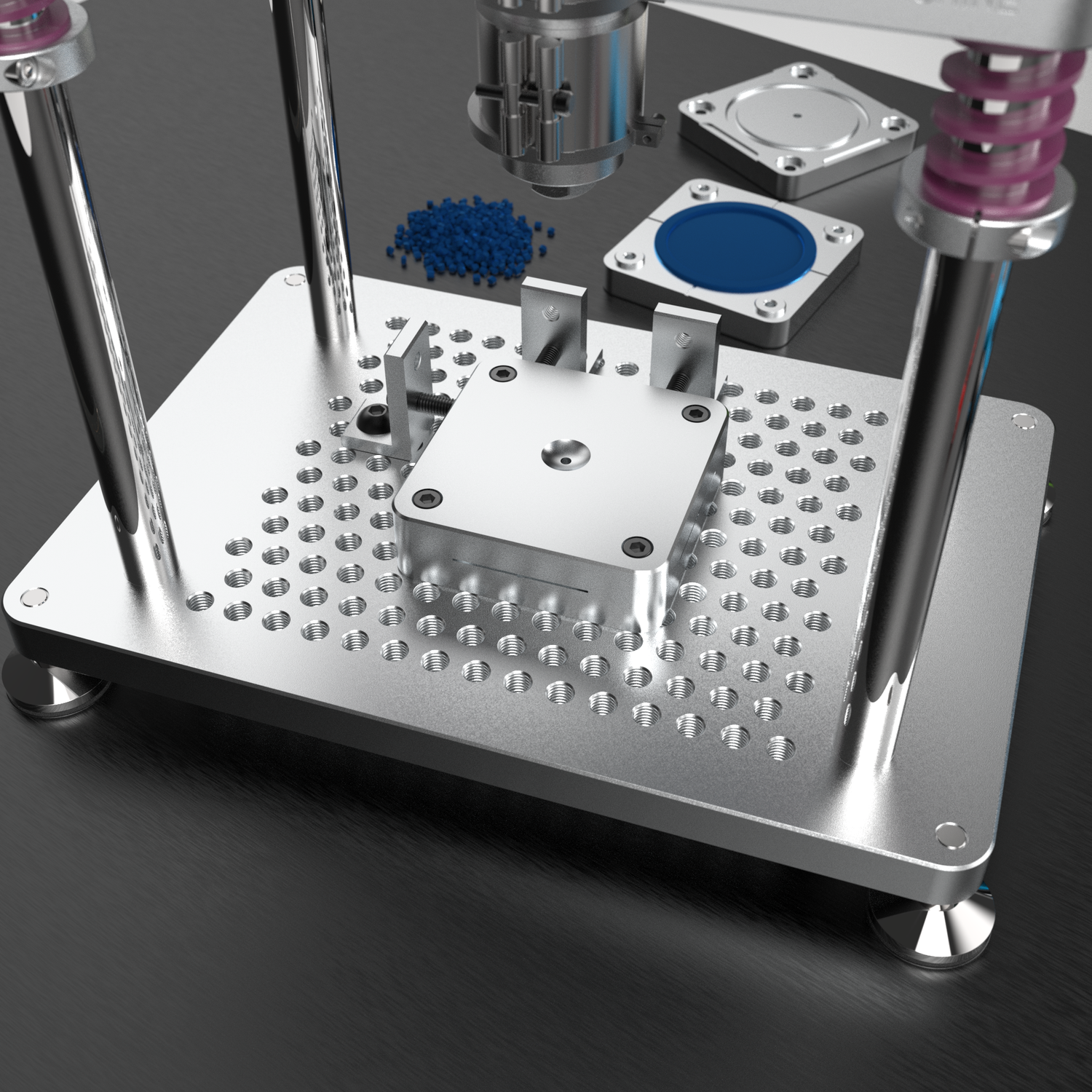

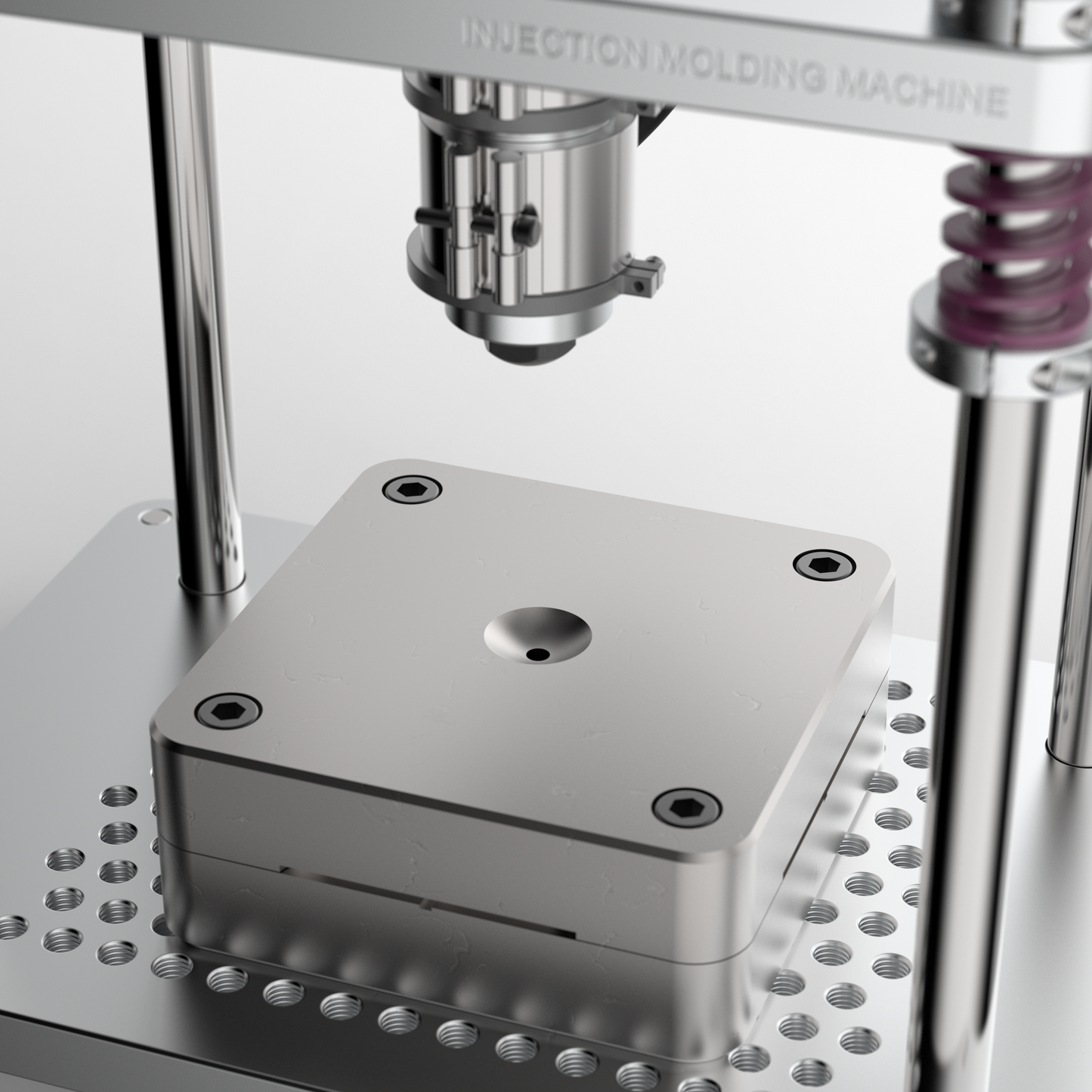

Customizable Mounting

Flexible Mounting System with M10 Grid Plate

The base plate is designed with a grid of M10 threaded holes, allowing for versatile mounting of molds, jigs, and additional equipment. This provides unmatched flexibility for customized manufacturing setups.

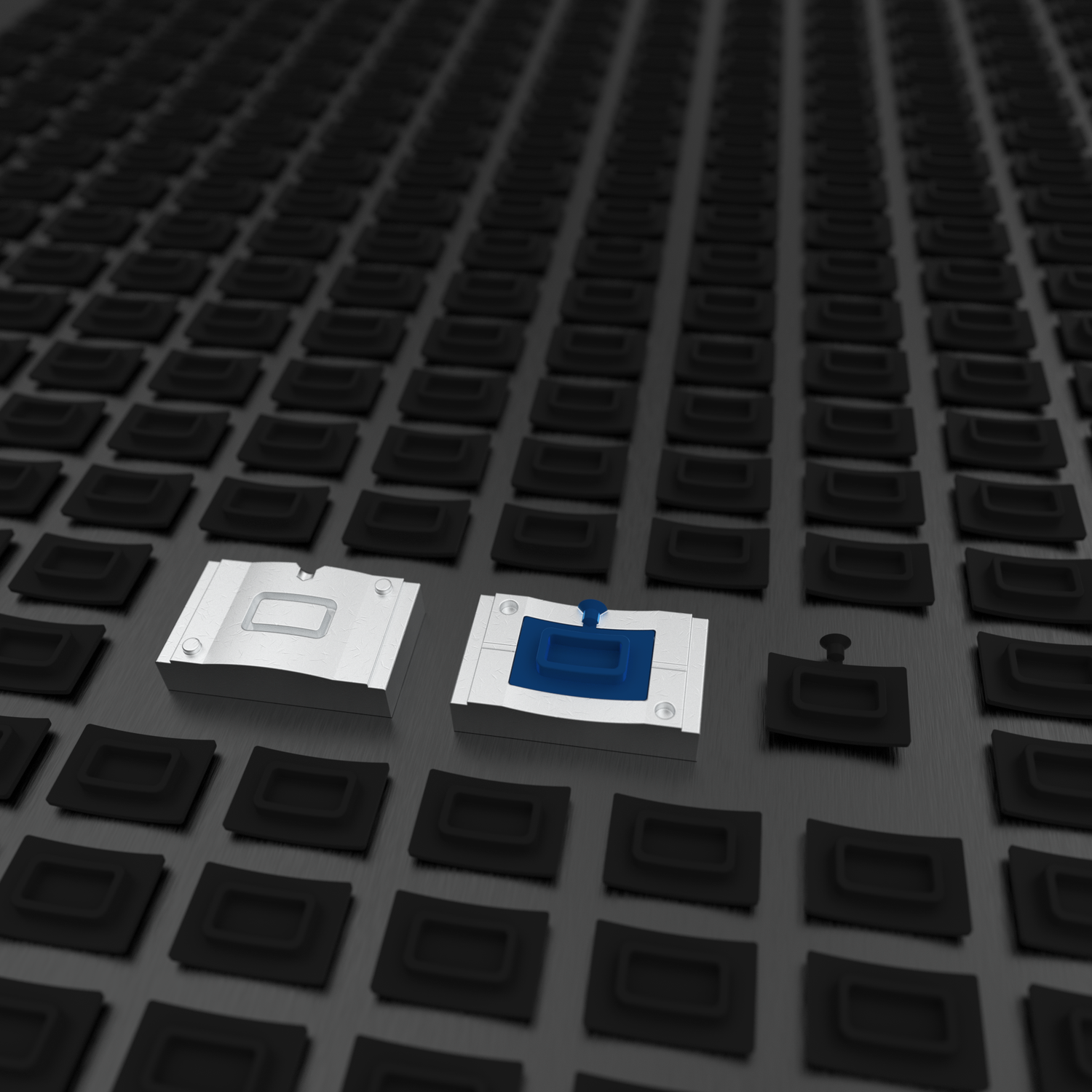

Consistent Results

Precision in Every Injection

Engineered for accuracy, the machine delivers consistent and precise molding results. Perfect for prototypes and small-scale production where tolerances matter most.

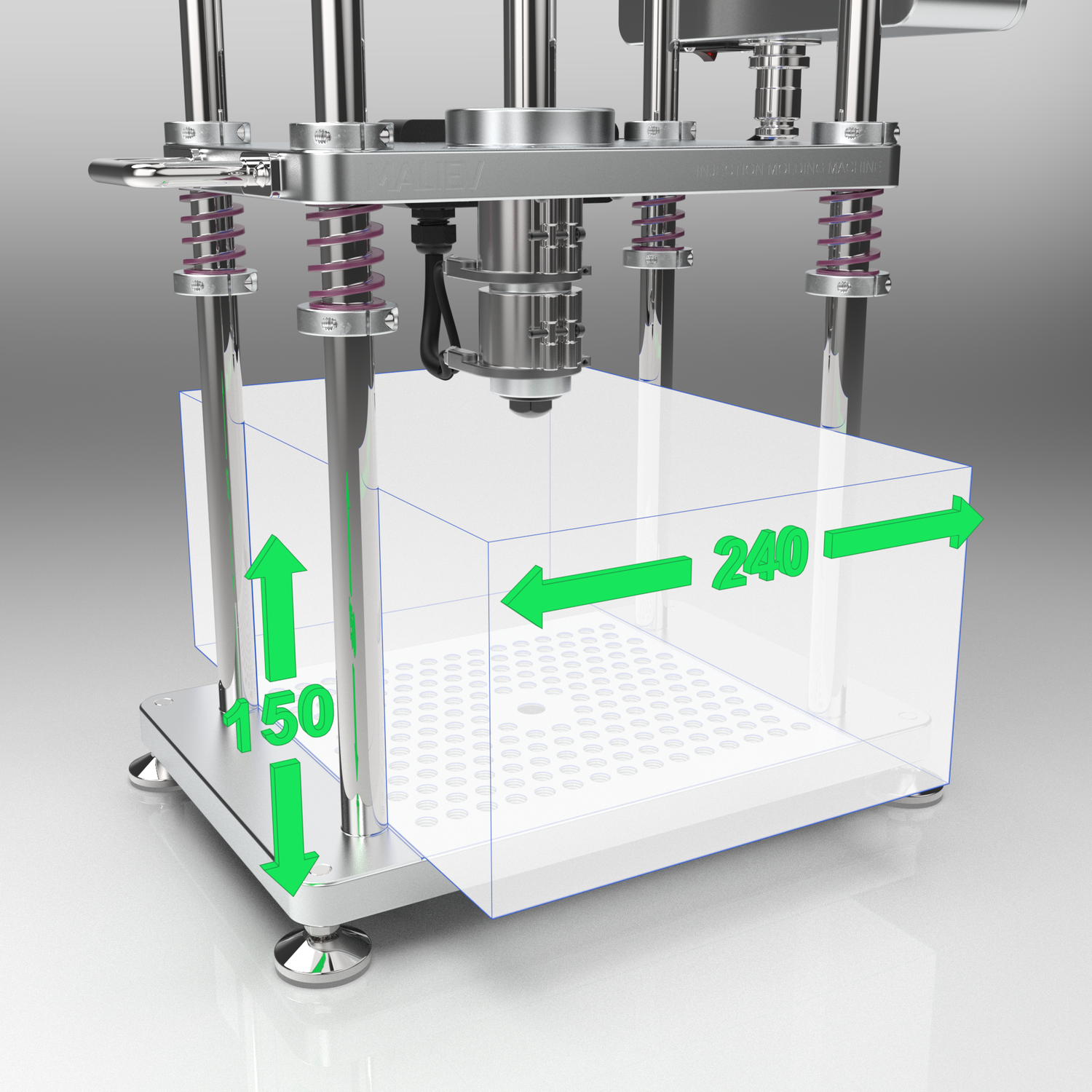

Flexible Mold Area

Large Mold Sizes

Accommodates large molds up to 240 x 150 mm (horizontal x vertical) with unlimited length, enhancing the ability to produce a wide range of parts.

Sustainable and Efficient

Eco-Friendly Manufacturing with Recycled Materials

Optimized for compatibility with recycled plastics, the machine supports sustainable production. Reduce waste and save costs without compromising on quality.

Build. Test. Produce.

Compact, powerful, and affordable. Learn how this pneumatic injection molding machine helps you start producing plastic parts fast with minimal setup and maintenance.

Need Assistance? We're Here to Help!

Have questions about our Injection Molding Machine? Chat with us directly on LINE Official Account for instant assistance!

Schedule a demo session with us!