Injection Molding at Home using Desktop Injection Machine

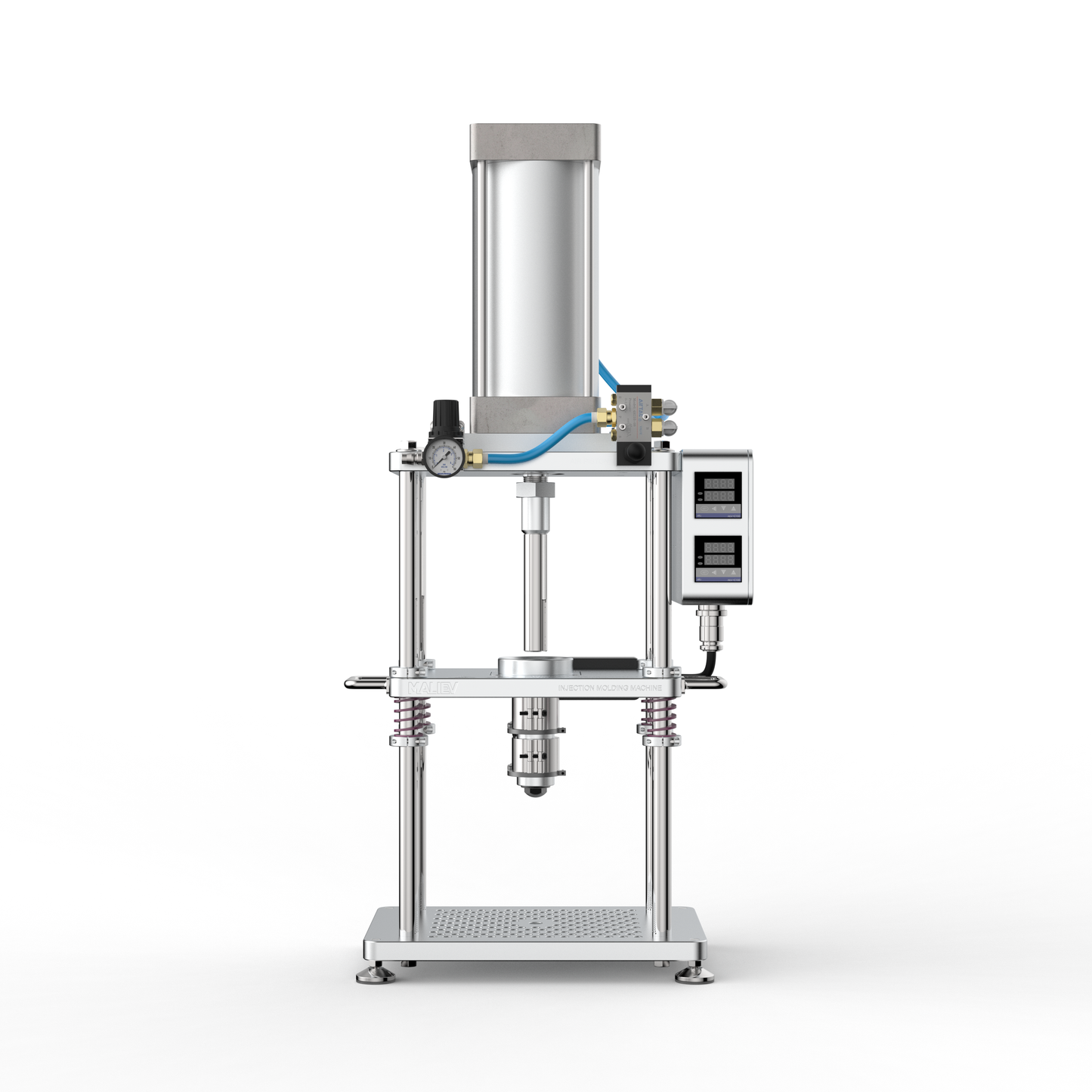

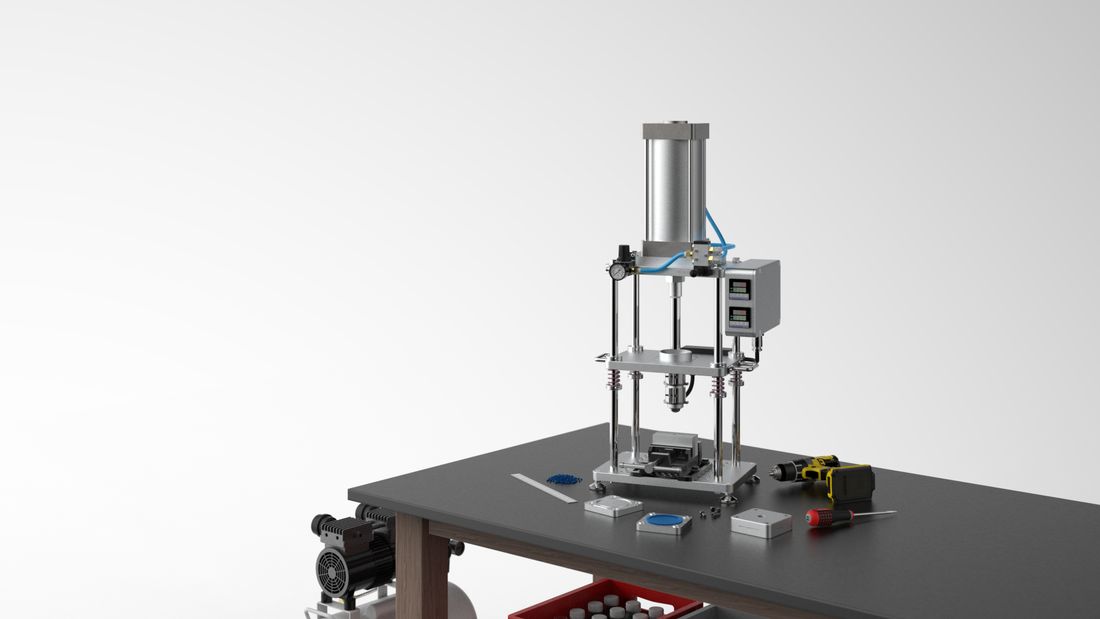

In the ever-evolving world of manufacturing, efficiency, precision, and cost-effectiveness are paramount. Introducing the Pneumatic Desktop Injection Molding Machine by MALIEV, a revolutionary tool that empowers businesses, hobbyists, and innovators to produce high-quality plastic components conveniently. This blog will delve into the features and benefits of this machine, illustrating why it’s the ideal investment for small to medium-scale production.

1. Compact and Powerful Design

The MALIEV Pneumatic Injection Molding Machine packs industrial-grade capabilities into a desktop-friendly design. Despite its compact footprint, this machine offers:

- Injection Pressure up to 876 kg-f: Ideal for precision molding.

- Maximum Shot Size of 30g: Perfect for small parts or prototyping.

- Cylinder Stroke of 200mm: Ensures flexibility for various mold sizes.

Whether you're producing small components for consumer goods, automotive prototypes, or educational tools, this machine’s robust performance will meet your demands.

2. Cost-Effective Manufacturing

Investing in large-scale injection molding systems can be prohibitively expensive for many businesses. With MALIEV’s desktop solution, you gain access to professional-grade molding capabilities without breaking the bank. Benefits include:

- Reduced Upfront Costs: Affordable price point compared to industrial machines.

- Low Operating Costs: Minimal electricity (220V@1000W) and pneumatic pressure requirements (0.7 Bar maximum input).

- Material Versatility: Compatible with common thermoplastics like ABS, PP, PLA, and HDPE, reducing material costs.

3. User-Friendly Features

Designed with simplicity and accessibility in mind, this machine includes:

- Dual Temperature Controllers: For precise plastic melting based on material specifications.

- Adjustable Injection Pressure: Adaptable for various molds and materials.

- Pneumatic Toggle Switch: Allows smooth and efficient injection control.

Even if you're new to injection molding, the clear operating manual and intuitive design make the learning curve manageable

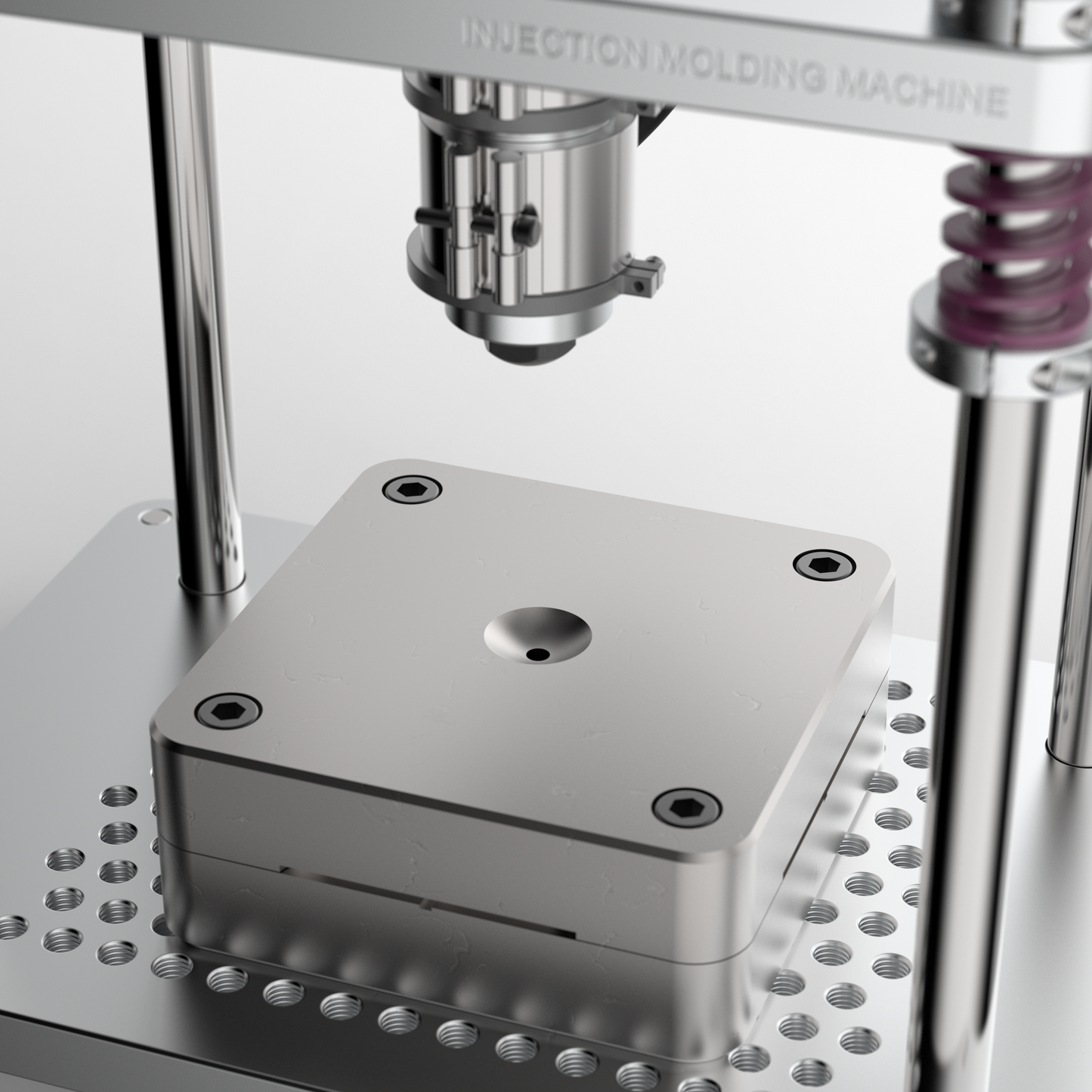

4. Versatility for Diverse Applications

This machine shines in its adaptability. With its ability to handle molds up to 240 x 240 x 150mm, it serves a broad range of industries:

- Prototyping: Rapidly create prototypes to refine designs.

- Small-Scale Production: Ideal for producing limited batches of custom parts.

- Educational Use: Provide students with hands-on experience in material science and manufacturing.

Additionally, the machine can accommodate overmolding or insert molding applications, making it a versatile choice for advanced users.

5. Built to Last

Durability and reliability are at the heart of MALIEV’s engineering. Features ensuring long-term usability include:

- Oil-Free Bushings and Return Springs: Minimize wear and tear.

- High-Quality Heater Bands and Sensors: Maintain consistent performance.

- Comprehensive Maintenance Schedule: Keep the machine in peak condition with minimal effort.

6. Environmental and Operational Safety

Safety is non-negotiable, and this machine adheres to the highest standards:

- PPE Recommendations: Protect operators from heat and debris.

- Ventilated Operation: Suitable for workshops with standard ventilation.

- Emergency Shutoff Features: Prevent accidents during operation or maintenance.

7. Backed by Exceptional Support

When you invest in MALIEV’s Pneumatic Injection Molding Machine, you also gain access to:

- 1-Year Warranty: Peace of mind for your purchase.

- Dedicated Customer Support: Assistance for installation, troubleshooting, and maintenance.

- Comprehensive Documentation: Includes user manual, wiring diagrams, and a material compatibility chart.